Recovery / Seperation of Protein/Cell Fragments / Solvents

- Life Science

- Water Quality Measurement

- Bio Decontamination Systems

- Rapid Microbial Methods

- Microbiology Instruments

- Measurement Solutions for RH, Temp, CO2, DP

- Probes for RH & Temperature

- Filters for Standard Probes

- Transmitters for RH & Temperature

- Transmitters for CO2 & DP

- Compact Data Loggers for RH & Temperature

- Universal Data Loggers for RH & Temperature

- High-end Data Loggers for RH & Temperature

- Wireless Data Loggers for RH & Temperature

- Handheld Instruments for Rh, Temperature & CO2

- Calibration for RH & Temperature

- Software

- LDP Probes

- Measurement Devices for Meteorology

- Air Quality Measurement

- Other Important Products

- Health Science

- Aseptic Preparation, Compounding Isolator

- Bio Waste Decontamination System

- Gas Leak Detectors

- IAQ Monitor

- Infection Control Enclosure (ICE-pod)

- Instantaneous Biological Counter In Environment

- Rapid Bio-Mass Detection System

- Room Bio Decontamination System (RBDS)

- Surface, Liquid Hygiene Monitoring Device (ATP+AMP Technology)

- VOC Monitoring (Portable, On Line & Personal Exposure)

- Food Science

- ERH Meter

- Head Space Oxygen Analyser (Modified Atmospheric Pressure-MAP)

- IAQ Monitor

- Microbial Air Sampler

- Microbial Detection using Chromogenic Media

- Microbial Identification Systems

- OTR Test for Packing Materials

- Rapid Simultaneous Total Coliform and E.Coli Systems Determination In Water

- Sanitizer Testing Kit

- Surface, Liquid Hygiene Monitoring Device (ATP+AMP Technology)

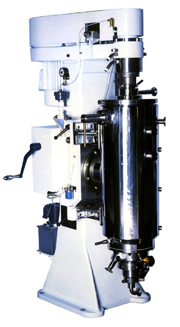

Centrifuges are extremely useful in industries for separation of solid-liquid & liquid-liquid separation at accelerated time spans.

ASM Tubular Centrifuge consists of a high-revolution rotor, a bearing support frame barrel, centrate collection cover and a vibration control drag. Centrifugal force 20,000 times greater than gravity separates material into liquid and solids continuously and discharges them in the batch process.

In food industry, ASM Tubular Centrifuge is used in separation and clarification of extract and animal, vegetable and fish oil.

In biological and pharmaceutical industries, it is used for capture of bacteria, retrieval of protein and recovery of cells and removal of cell fractions.

Various models are available depending on requirement for "Liquid-Solid", "Liquid-Liquid" or "Liquid-Liquid-Solid" separation.

1. Open Type(AP):

- Integration of the centrate collection cover and the discharge port: easy disassembly and cleaning of the discharge component, and visible liquid purification process

- Many installations in the extract separation/clarification and the animal/vegetable oil refinery processes

2. Pressure-tight Type (PT):

- Mechanical seals keep gasses inside perfectly

- 0.2Mpa (2kg/cm2) pressure-tight design: safe separation of hazardous/toxic substances

3. Refiner Type (RF):

- Wide-open discharge port for heavy phase liquid: smooth and continuous discharge of soft plastic or visco-elastic material

- Main application: de-gumming and deoxidization of vegetable/animal oil. Gravitational discharge of agglomerated gum and foods

4. Plasma Type (PL):

- Cooling coils in the frame barrel: easy liquid temperature control

- Sanitary provision for wet parts: easy overhaul and cleaning

5.Sterilization Type (NP):

- SIP compliant mechanical seals in the bearing assembly: 121 vapor pressure resistive

- Airtight and aseptic operation

- Clean room/safe cabinet type is also available: the bowl in a horizontal position

- Collection, condensation, and washing of cell

- Removal of cell fragments

- Collection and purification of inclusion bodies

- Extraction, dehydration and recovery of solvents

- Separation of chlorella and yeast

- It is used for recovering, thickening and cleaning of cells, removal of cell fraction

- For capture of bacteria and recovery of protein